Geotechnical Engineering Laboratory

As a teaching facility, undergraduate students discover soil properties using hands-on, active learning through laboratory experiments and demonstrations, including soil classification, Atterberg limits, permeability, moisture-unit weight relationships, unconfined compression, and direct shear. Graduate students investigate advanced soil testing techniques, such as one-dimensional consolidation and triaxial compression testing. As research facility, multiple load frames and data acquisition systems facilitate both conventional and custom geotechnical testing approaches.

Key Capabilities:

- Soil characterization testing – Atterberg limits, grain size analysis, water content, specific gravity, moisture-unit weight (Proctor) relationships

- Permeability testing using constant head and falling head methodology

- Triaxial compression testing of soil at confining stresses up to 3.4 MPa (500 psi)

- One-dimensional consolidation testing to vertical stresses up to 7 MPa (1000 psi)

- One-dimensional compression testing of foamed glass aggregate

- USDA permitted facility for the acceptance and testing of non-domestic soil samples.

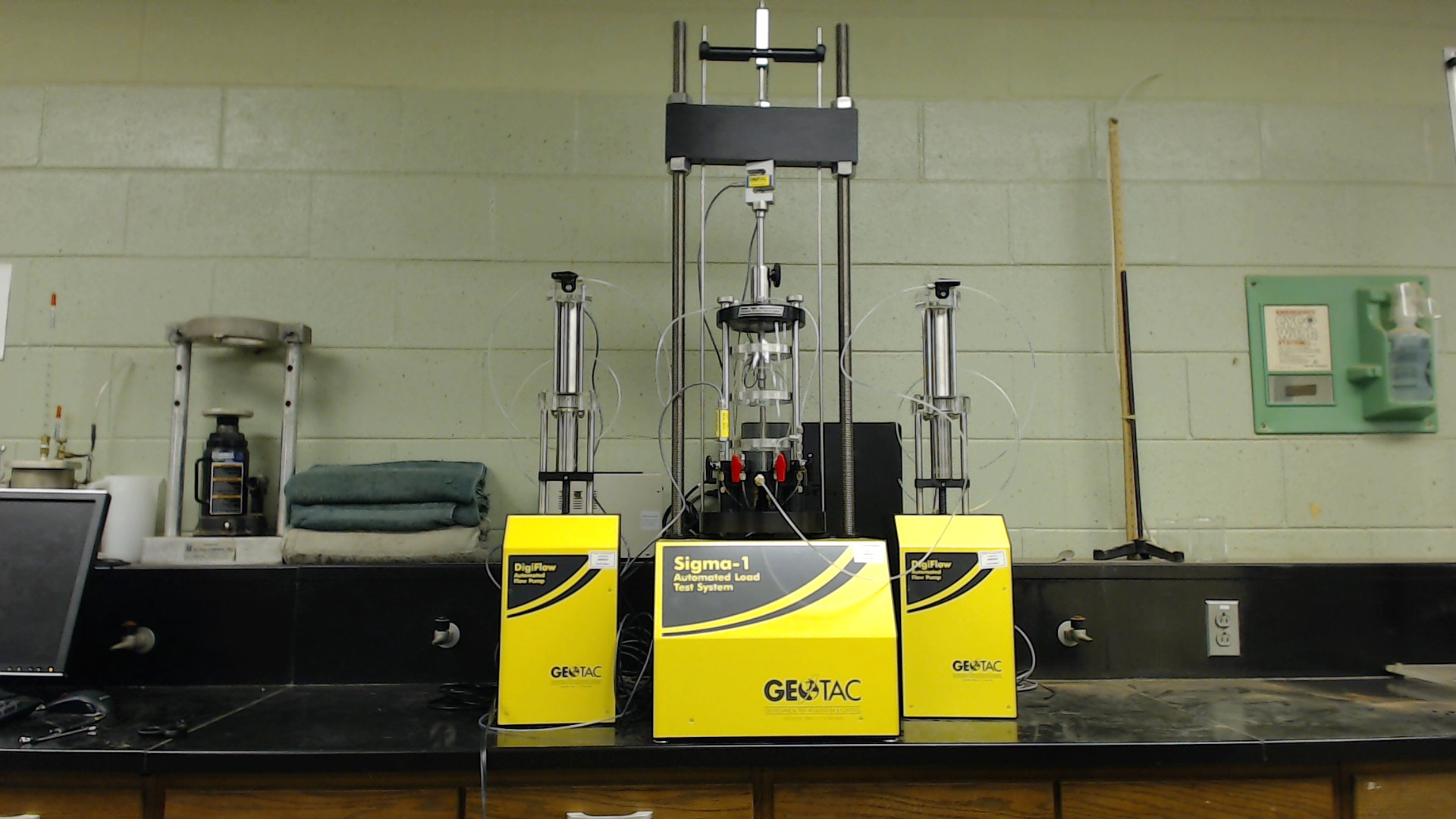

Key Equipment:

- Automated 22.4 kN (5,000 lb) GeoTac mechanical load frame

- Two automated 8.9 kN (2,000 lb) GeoJac mechanical load frames

- Two 44.5 kN (10,000 lb) Humboldt mechanical load frames

- Two Humboldt 2750 direct shear apparatuses

Ancillary Equipment:

- Testnet-GP geotechnical data acquisition software

- Load cells with capacities ranging from 500 to 100,000 lb

- Benchtop oven for drying soil samples

- Harvard miniature compaction equipment for compacted soil specimens

Contact:

Daniel R. VandenBerge, Ph.D. dvandenberge@tntech.edu